Campisa loading bays

The best technologies and materials used in the production of bays, loading ramps and industrial doors

Campisa loading bays

The best technologies and materials used in the production of bays, loading ramps and industrial doors

Campisa: equipment for bays and loading points

Since 1972 Campisa has been building logistics equipment and equipment for loading points. The acquisition of new patents and the development of innovative design techniques, have allowed the company to become a reference point in the global market over the years.

For this reason, nowadays Campisa offers solutions to companies worldwide for construction development and installation concerns, hence contributing to construction costs and installation times reduction.

Loading bays and ramps, Prefabricated Pits, Fidelity® electro-hydraulic systems and sectional doors are designed to last over time and maximize the performance of logistics hubs.

Thanks to the use of innovative materials such as S355 steel for the loading docks, Campisa is able to guarantee excellent product’s resistance to deterioration, protecting them from adverse environmental factors.

The production process and all the processing phases comply with the ISO 9001 quality standards and with other standards such as “EPD” , favoring a lower environmental impact.

Discover the full range of Campisa products for your business.

Campisa equipment

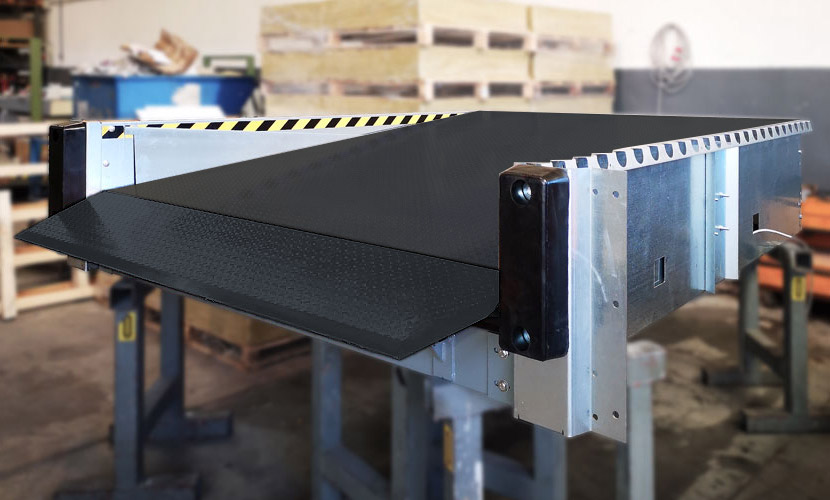

LOADING RAMPS

Campisa offers different types of loading ramps to match different construction systems of the pits.

The ramps are designed for loading and unloading goods and compensate the unevenness between the warehouse platform and the height of the vehicle platforms, following European norms and regulations as well as high safety and quality standards.

Each ramp is tested directly by our experienced engineers at the Research and Development department and this allows us guaranteeing a safe and well performing product that lasts, without need of frequent maintenance.

All industrial dock levelers are designed to be compatible with the characteristics of the building structure in the loading docks area, therefore, we are able to offer a wide variety of ramp models that can be installed both in new constructions and in existing loading areas.

For the year 2022, the color of our Campisa ramps is “anthracite”, RAL 7016.

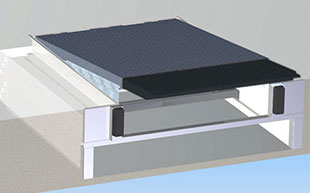

Our Prefabricated Pit increases precision and quality, while reducing the installation time and site preparations costs.

Prefabricated pits

The Campisa Prefabricated Pit is one of our most successful patented products.

Our Prefabricated Pit system for loading docks replaces the traditional pit edge frame to ensure easy and precise installation of both the pit and loading ramp.

Compared to the classic pit edge frame, his innovative system significantly reduces time and cost for building preparation and the final result guarantees maximum efficiency during the loading and unloading operations.

Fidelity®

Campisa is the first company that patented a special electro-hydraulic motorization: “FIDELITY®”, combined with a command console for the management and control of loading ramps and sectional doors.

Unlike traditional spring-loaded doors, this innovative managing system for loading points eliminates any type of risk and work-forced-pauses.

The Fidelity® operator is available in two versions and each unit can control two doors or one door plus a loading ramp.

The “Fidelity® Compact” is our third version. The Fidelity Compact box integrates the control unit, the hydraulic motor and the cylinder allowing a fast and easy installation ensuring maximum safety.

Industrial doors

Campisa designs and provides a wide range of industrial sectional doors capable to ensure maximum closing performance, room insulation and rapid transit.

Campisa industrial doors are the best solution to optimize company’s energy saving, maintenance costs and footprint on the ground.

Thanks to the perfect combination offered by the Fidelity® system, all sectional doors and industrial doors can be managed and operated by a single command console.

Dock house-vandock-sealants

- Dock Tunnel.

- Retractable sealants.

- Pillow sealants.

- Inflatable sealants.

Accessories

Loading dock safety is never enough. For this reason Campisa has a wide range of accessories and safety systems for loading points and sectional doors.

Each safety accessory or device is designed with the aim of improving functionality and safety during logistical operations.